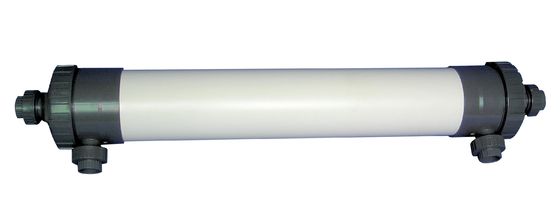

The core SINOMEMB ® series SNU-HO-2-860 hollow fiber UF membrane element is suitable for systems

with a capacity greater than 50m 3 /hr (220 gpm) . Compared with longer membrane modules, shorter membrane

modules (60 inches) provide higher separation efficiency and can adapt to a wider range of influent water quality ,

helping customers to achieve more economical membrane system design , and can be widely used on the surface

Various water treatment applications such as water, well water, seawater , industrial wastewater, and secondary and

tertiary treatment of sewage .

Operation Guide

During the operation of the UF system, it is necessary to avoid sudden changes in pressure during system

start-up, shutdown, operation, cleaning, maintenance, etc., as well as exceeding the maximum withstand pressure

specified in this manual, to prevent possible membrane breakage, sealing, etc. End fall off, membrane shell

cracking and other serious damage consequences; this series of products have been treated with anti-corrosion and

membrane wire protection before leaving the factory, and the inner membrane wire of the module is in a semi-dry

state. For manual operation, the water production rate should be set to 50% of the design water production rate, and

the initial water production must be discharged directly and cannot be used as product water.

Product usage tips

The normal start-up and normal cleaning and maintenance of the UF system are the key to ensure the

long-term normal use of membrane products. Before starting the system, it should be ensured that the parameters of

each valve, instrument, pre-processing equipment, signal transmission equipment, power equipment, etc. meet the

design specifications and requirements, so as to ensure the safe, stable and up-to-standard operation of the overall

system. Please refer to the product technical manual for the debugging and testing work of the system in the early

stage.

Disclaimer

Failure to operate in strict accordance with the operating limits and guidelines set forth herein voids our limited

warranty. If the UF system is out of service, please inject protective liquid inside the membrane module for

anti-corrosion treatment, so as to avoid the increase of maintenance cost caused by the large number of

microorganisms in the system.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!